One Printed Dessert You Say? Comin’ Right Up!

Let’s all admit just how addicted we are to sugar. From beverages to desserts, sugar or sugar substitutes dominate our food intake. It’s just something that most of us can’t get enough of. Its ability to be melted into glass-like substances enables confectionery artists to come up with tasty displays worthy of museums, or being served as 3D printed dessert.

Also, this is in fact the very same property that seems to have made it interesting to scientists at the University of Illinois as well, who have now created a kind of 3D printer capable of printing detailed biological structures out of sugar.

Photo by L. Brian Stauffer

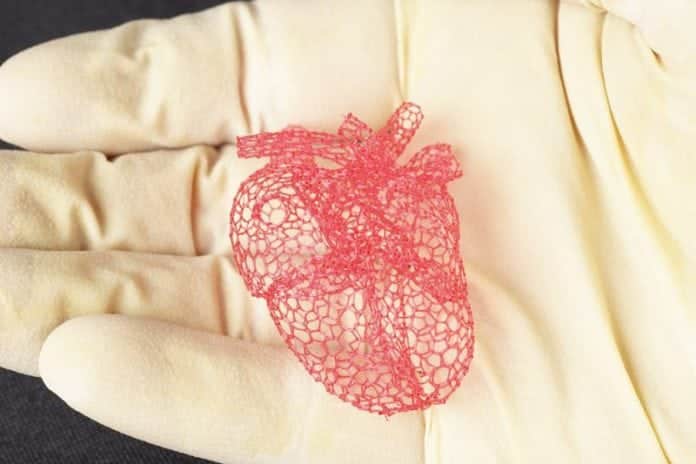

“This is a great way to create shapes around which we can pattern soft materials or grow cells and tissue, then the scaffold dissolves away,” said Rohit Bhargava, a professor of bioengineering and director of the Cancer Center at Illinois.

“For example, one possible application is to grow tissue or study tumors in the lab. Cell cultures are usually done on flat dishes. That gives us some characteristics of the cells, but it’s not a very dynamic way to look at how a system actually functions in the body. In the body, there are well-defined shapes, and shape and function are very closely related.”

Despite the existence of other 3D printers capable of working with sugar, the team in this particular case- unlike typical commercial printers- used isomalt – a sugar substitute derived from beets and commonly found in throat lozenges.

These sugar structures, once melted down and printed, cool and solidify, thereby creating a sturdy scaffold that makes these structures particularly useful in device manufacturing and in health-related fields such as biomedical engineering and cancer research.

“After the materials and the mechanics, the third component was computer science,” Gelber said. “You have a design of a thing you want to make; how do you tell the printer to make it? How do you figure out the sequence to print all these intersecting filaments so it doesn’t collapse?”

The Illinois team partnered with Greg Hurst at Wolfram Research in order to design an algorithm which, in turn could be used to design scaffolds and map outside printing pathways.

One advantage such free-form constructions hold is their capacity to create thin tubes with curved cross-sections, something impossible with traditional polymer 3-D printing.

After the sugar melts, it leaves a collection of connected cylindrical tunnels and tubes which may be utilized for example blood vessels to transfer nutrients in tissue or to generate stations in microfluidic devices.

Video courtesy of Matthew Gelber

Additionally, another benefit of this technology is the ability to control the mechanical components of every area of the construction by making minor changes in the printer parameters.

Bhargava’s team is currently utilizing the scaffolds in many different microfluidic devices and cell cultures, and it’s working to create coat for those scaffolds to control just how fast they dissolve.

The Additive Manufacturing newspaper is part of a series of books based on Gelber’s thesis work that details how to construct the printer and also the preparation calculations required to run it as the investigators expect that others may use their versions to construct printers and explore many software for isomalt structures.

“This printer is an example of engineering that has long-term implications for biological research,” Bhargava said. “This is fundamental engineering coming together with materials science and computer science to make a useful device for biomedical applications.”