Mini Liver By 3D Bioprinting

Researchers from Brazil have successfully created Mini Liver With the help of 3D Bioprinting. The Mini Liver performs all the liver’s typical functions, such as producing vital proteins, storing vitamins, and secreting bile, among many others.

The breakthrough technology developed by the researchers can produce hepatic tissue in the laboratory in only 90 days. This technology in the future may become an alternative to organ transplantation.

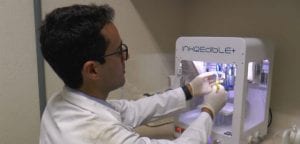

This study by Brazil researchers combined bioengineering techniques, such as cell reprogramming & the cultivation of pluripotent stem cells, with 3D bioprinting. Thanks to the newly adopted strategy, the hepatic tissue produced by the bioprinter maintained functions for longer than reported by other scientists in previous studies.

Mayana Zatz, director of HUG-CELL, said that the study is on the right track to highly promising results, although in-depth research is the need of the hour. The new Mini Liver By 3D Bioprinting technology will have zero probability of rejection, given that the cells come from the patient.

The innovative part of the research resided in how the cells were included in the bioink used to produce tissue in the 3D printer. Due to this, the functionality of the Mini liver

is maintained for a more extended period. The scientists thereby avoided a problem faced by most human tissue bioprinting techniques. Some of them include a gradual loss of contact among cells which consequently leads to loss of tissue functionality.Spheroid formation in this research already occurred in the differentiation process, when pluripotent cells were transformed into hepatic tissue cells.

Mini Liver By 3D Bioprinting- Liver In 90 Days!

According to the researchers, the overall process from the collection of the patient’s blood to functional tissue production takes approximately 90 days. It can be divided into 3 stages: differentiation, printing, & maturation.

Initially, the blood cells are reprogrammed to regress to a stage of pluripotency- a characteristic of stem cells, becoming induced pluripotent stem cells (iPSCs).

The second stage of producing the Mini Liver By 3D Bioprinting consisted of inducing differentiation into liver cells. The spheroids are then mixed with bioink, a hydrogel-like fluid, & printed out. The resulting structures mature in culture for 18 days.

Majority of the conventional methods for printing live tissue use immersion & cell dispersion in a hydrogel to recapitulate the microenvironment. This ensures tissue functionality. However, previous experiments have shown that loss of cell contact, as well as functionality, occurs when dispersion is performed cell by cell.

In this study, the scientists developed mini-livers by 3D bioprinting technique using blood cells from three volunteers as raw material and compared markers relating to functionality, such as the maintenance of cell contact and protein production and release.