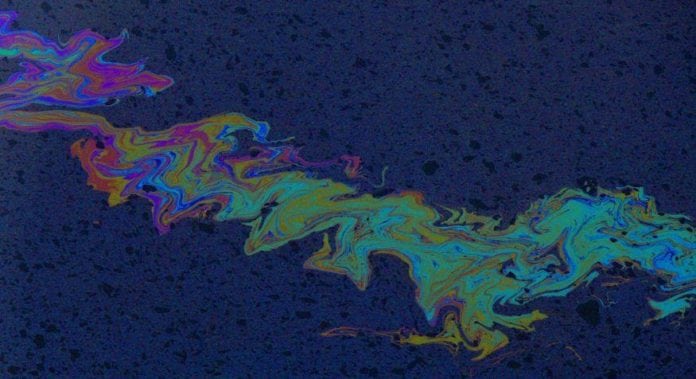

Scientists Develop a “Smart” Membrane, Promising a Solution to Oil Spills

“This technology offers an effective and eco-friendly way to reduce the negative impacts of oily water and wastewater, which are being produced by domestic, municipal and industrial processes every day,” says Chun Haow (Bryan) Kung, a chemical engineering master’s student at UBC who led the study.

Other separation membranes which may selectively permit either water or oil to pass through them do exist.

But, their shifting capability is generally conferred by means of a chemical coating which isn’t just poisonous and short-lasting, but in addition requires a huge number of minutes to trigger and large voltages, corrosive solvents or other negative stimulation or conditions to operate.

To make things worse, the separation that’s attained isn’t especially great, producing water and oil of relatively low purity.

This membrane was designed using a copper net with dendritic arrangement is ready with an deposition plan for separation. As we know, the electrochemical manipulation of the oxidation state of the aluminum oxide shell period results in affinities towards oil and water.

And this aluminum mesh was later tuned by the team in order to attest equally superhydrophobic and superoleophilic properties to allow oil-removal. Further, the researchers

say that switching into submerged and superhydrophilic superoleophobic lets water-removal.“This membrane works without needing a continuous electric current, or any specialized equipment or conditions,” says Kung. “Also, the membrane is really robust — we put it through 30 consecutive separation cycles, using both light and heavy oils, without losing efficiency — so it has tremendous potential for industrial use, too.”

Furthermore, preparing this particular membrane is a fast, scalable procedure between broadly accessible aluminum stuff: a copper net is immersed in an electrolyte solution and exposed to a series of 2 little voltages for a total of two minutes.

Even the “tunable wettability” of the subsequent membrane could possibly be credited to this multiscale roughness of the mesh construction as well as the aluminum oxides which are bound into it, that transform to water-loving metallic copper when voltage is used.

“As more and more oily wastewater is produced by the oil and gas, mining, pharmaceutical and other industries, the need for an effective way to address the problem becomes all the more pressing,” says Walter Mérida, a mechanical engineering professor at UBC and the director of the university’s Clean Energy Research Centre, who supervised the study. “We hope that one day this mesh will help protect land and living organisms from oil contamination.”