Graphene Spikes that Devour Bacteria to Keep Out Infections

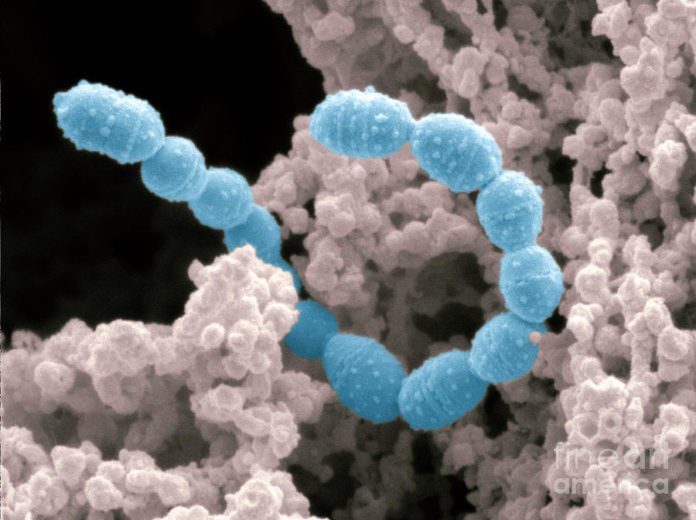

The key first step in developing bacterial infections related to implants and medical devices is the attachment of planktonic bacterial cells, and subsequent formation of biofilms. Now, researchers have shown that a layer of vertical graphene flakes forms a protective surface that makes it impossible for bacteria to attach. Instead, bacteria are sliced apart by the sharp graphene flakes and killed. Coating implants with a layer of graphene flakes can therefore help protect the patient against infection, eliminate the need for antibiotic treatment, and reduce the risk of implant rejection.

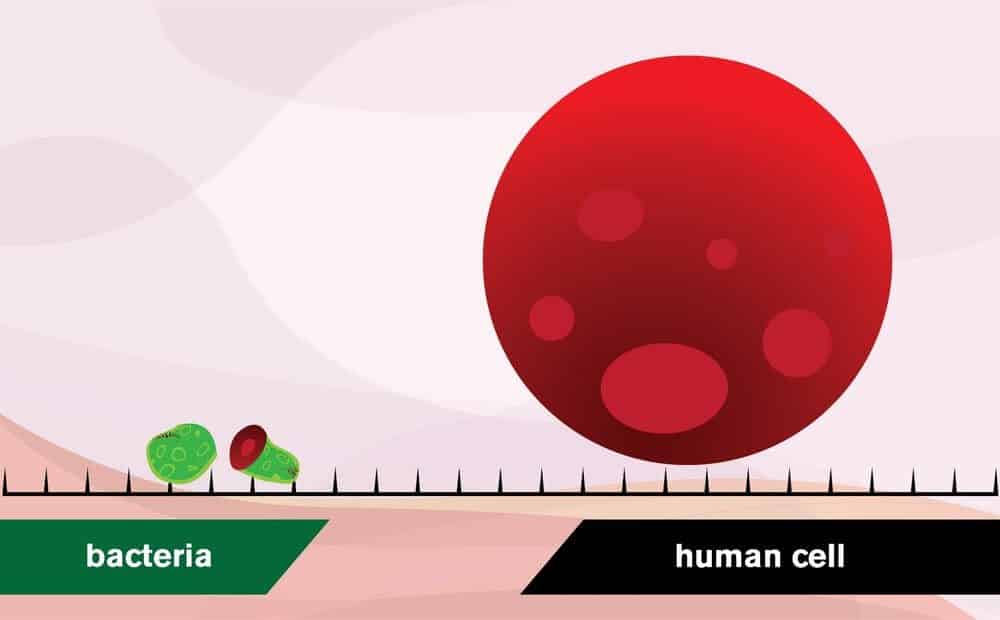

The sharp flakes are built in a way that they do not cause any damage to human cells. The reason is simple: one bacterium is one micrometer – one thousandth of a millimeter – in diameter, while a human cell is 25 micrometers. So, what constitutes a deadly knife attack for a bacterium, is therefore only a tiny scratch for a human cell. Additionally, good bacteria are also killed by the graphene. But that’s not a problem, as the effect is localised and the balance of microflora in the body remains undisturbed.

“We discovered that the key parameter is to orient the graphene vertically. If it is horizontal, the bacteria are not harmed,” says Ivan Mijakovic, Professor at the Department of Biology and Biological Engineering.

“Graphene has high potential for health applications. But more research is needed before we can claim it is entirely safe. Among other things, we know that graphene does not degrade easily,” says Jie Sun, Associate Professor at the Department of Micro Technology and Nanoscience.

“We want to prevent bacteria from creating an infection. Otherwise, you may need antibiotics, which could disrupt the balance of normal bacteria and also enhance the risk of antimicrobial resistance by pathogens,” says Santosh Pandit, postdoc at Biology and Biological Engineering.

To produce vertical graphene forms, the team used a process known as plasma-enhanced chemical vapour deposition. An electric field is applied over the sample, which causes the gas to be ionised near the surface. With the plasma, the layer of carbon grows vertically from the surface, instead of horizontally as with traditional chemical vapour deposition techniques.

With its good conductivity and a strength measuring 200 times that of steel, graphene has potential applications across many sectors including medicine, electronics, energy and sensors. However, the researchers cautioned that more tests are needed before it can be used in the body.