Say Bye to Injection Woes, 3D-Printed Dissolvable Microneedles are Here

No one like getting shots- to be honest, as an adult they’re still less fun. Even when you’re old enough to understand that they’re a necessary evil to keep you (and others around you) healthy, it doesn’t change the fact that getting a needle shoved into your skin hurts — plain and simple.

But then, given the rate at which we are advancing both medically and technologically, in a few years’ time injections could become a thing of the past, thanks to new, painless alternatives.

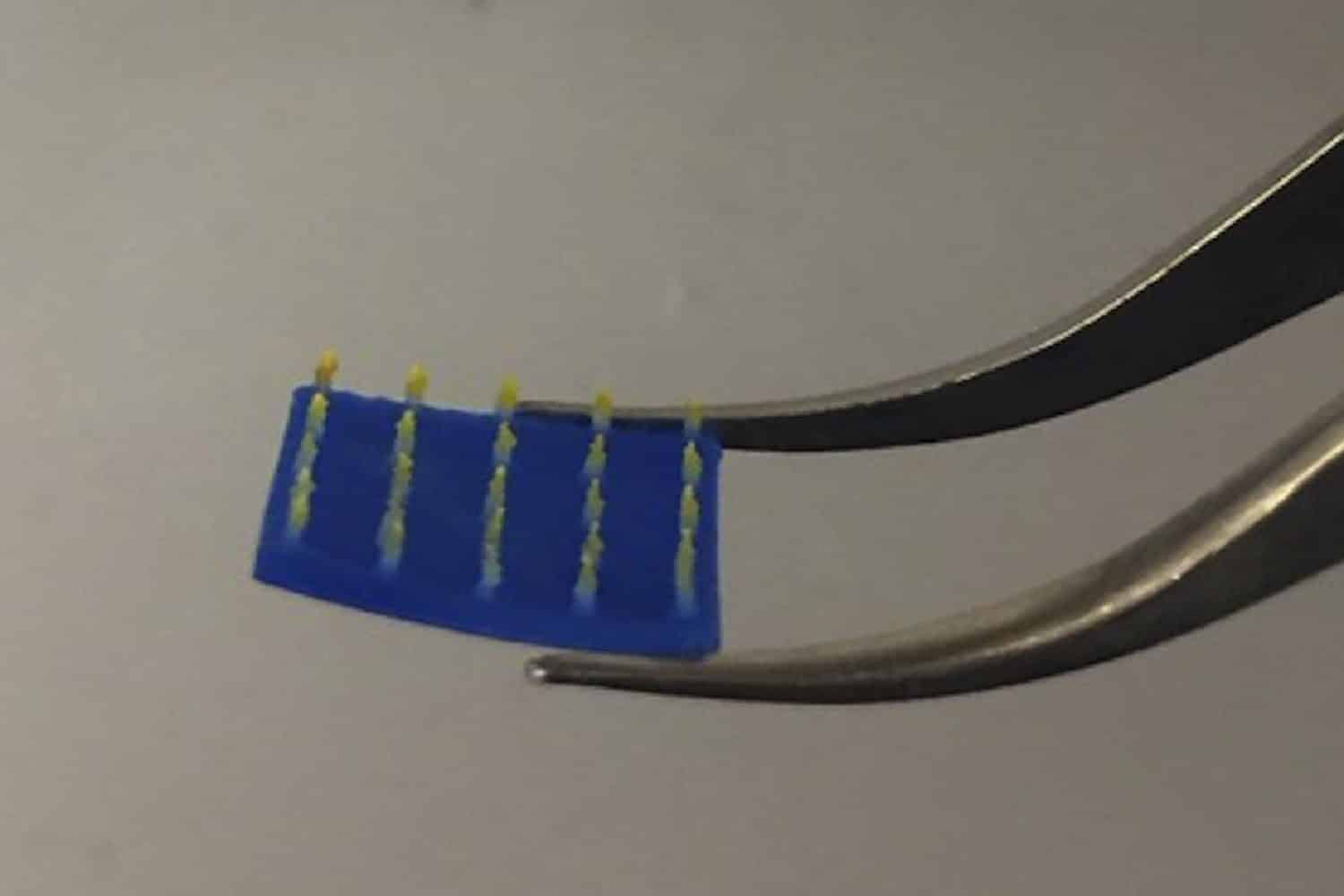

Now, in this direction, a team of researchers from the University of Texas at Dallas have designed painless, biodegradable microneedles that can break off in the skin and dissolve to administer drugs.

The UT Dallas team’s 3D printed microneedles are also biodegradable, and will break off underneath the skin and dissolve over time to release the drugs…a far cry from today’s conventional syringes. They are painless, because the microneedle is so thin that patients can’t even feel it when it breaks off.

The team of researchers at Dallas, led by Jeremiah Gassensmith

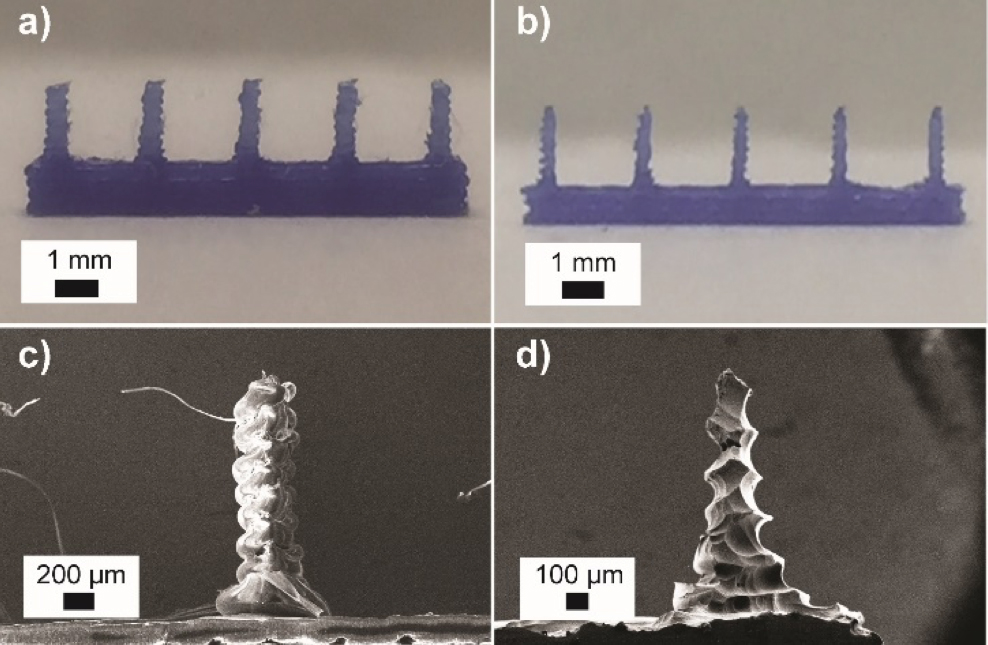

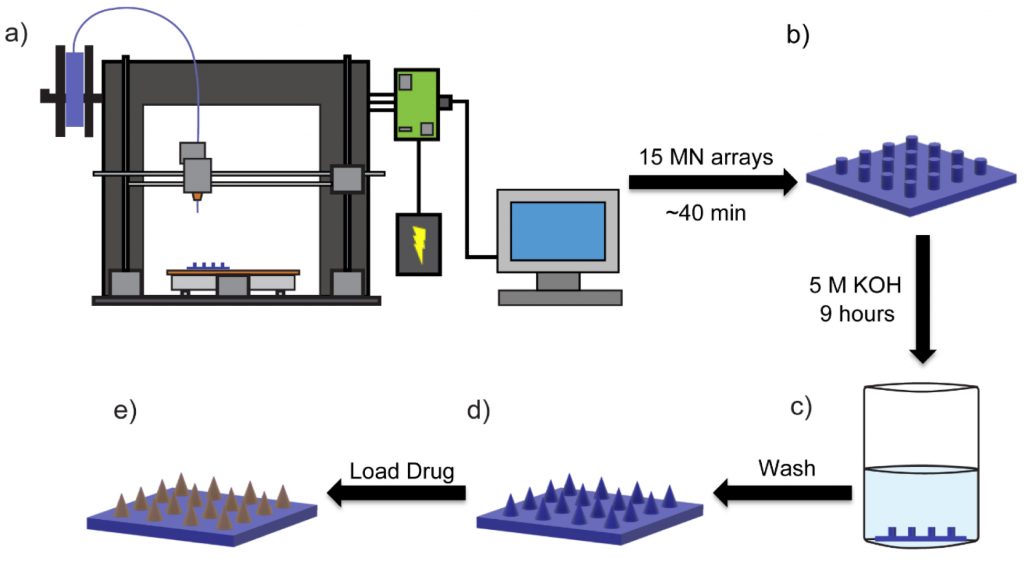

, looked to use 3D printing techniques to make microneedles from polylactide, a non-toxic, biodegradable and renewable polymer which is approved for use in dissolvable stiches. Unfortunately, the printing techniques that are capable of producing features smaller than 100 micrometres are not compatible with the biodegradable polymer required. Gassensmith’s team instead used fused deposition modelling (FDM), a 3D printing technique that works well with polylactide, but has lower resolution.The team’s manufacturing method is a five step process that starts with FFF using a Lulzbot TAZ 5 3D printer. It takes 40 minutes on average to make a batch of 15 microneedle arrays. The arrays are then left to soak in a chemical solution for 9 hours which etches the surface, and carves the microneedles to a fine point between 1 and 55 μm wide. In the penulitmate step, the microneedles are washed. Then they can be loaded with a drug for application in the skin.

Usually producing microneedles would require specialized equipment in the form of a cleanroom. The issue is that this is not something that many smaller companies have access to. “We basically found a way to cut out the multimillion-dollar clean room with a $1,000 Lulzbot,” Gassensmith explained. “We print microneedles, do some post-print processing on them to make them super-sharp, and then we show we can load small molecules into them and release them into the skin over time.”

“We’d love to get plastic filaments that are loaded with specific drugs that are typically only effective when administered by IV,” Gassensmith said. “Instead of getting multiple shots, your doctor would print out a therapeutic microneedle patch and mail it to you and you could apply it yourself at home. One of the great advantages of microneedles is you don’t need to be trained to use them. They’d be great for deployment where formulating IV drugs would be a hassle, like in delivering vaccines to developing countries. The 3D-printing technology is ready to be commercialized right now, and we are actively working on finding candidate drugs to use for our spools.”

Where did you know about microniddle patch, we are studied about the acceptance of microniddle patch at Delhi NCR.