Researchers Develop Biocompatible Ink for 3D-Printing Using Bacteria

The secret ingredient is: Living bacteria.

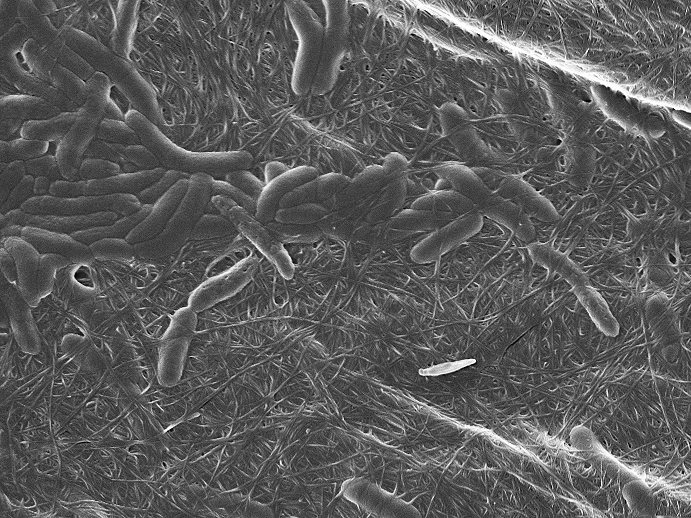

Bacteria are able to thrive in virtually any ecological niche because of their adaptive and diverse metabolic activity. Owing to such a metabolic diversity, richer than in any other types of organisms, bacteria create, for example, physical matter in the form of biofilms that warrant survival even in hostile environments.

Now, researchers at the ETH Zurich , encashing on this property of theirs have developed “living ink”, something they use to describe a new 3-D gel laced with bacteria that turn out molecules helpful in wound healing and water cleanup. The material can be customized for different uses by adding a variety of bacteria, and sprayed out of the nozzle of a 3-D printer into many useful shapes.

The bacteria-laden ink allowed researchers to produce “mini biochemical factories with certain properties, depending on which species of bacteria the scientists put in the ink,” and that could mean 3D printing personalized skin in the future.

ETH Professor André Studart, Head of the Laboratory for Complex Materials, and team have used the bacteria Pseudomonas putida and Acetobacter xylinumin their work. The former can break down the toxic chemical phenol, which is produced on a grand scale in the chemical industry, while the latter secretes high-purity nanocellulose. This bacterial cellulose relieves pain, retains moisture and is stable, opening up potential applications in the treatment of burns.

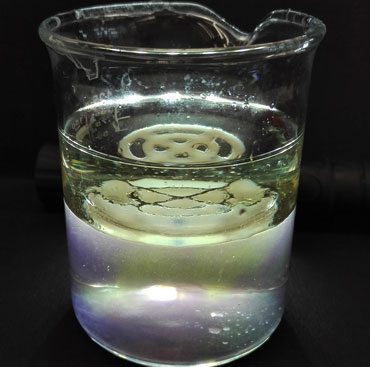

Called “Flink,” which is an acronym for “functional living ink,” this new ink is composed of a biocompatible hydrogel that provides structure. The hydrogel itself is composed of hyaluronic acid, long-chain sugar molecules, and pyrogenic silica. The culture medium for the bacteria is mixed into the ink so that the bacteria have all the prerequisites for life. Using this hydrogel as a basis, the researchers can add bacteria with the desired “range of properties” and then print any three-dimensional structure they like.

It makes a good scaffold for skin grafts or engineered tissue. Coating a transplanted organ with cellulose can also reduce the risk of its rejection. For all of these uses, a close fit to a body part is better. A hydrogel containing the bacteria could be used to fabricate cellulose dressings in the exact shape of a body part or organ based on a CT scan.

To test this idea, the researchers made a hydrogel with A. xylinum. Using a 3-D printer than can handle curvy surfaces, they deposited a thin layer of the hydrogel over a doll’s face. After four days in a warm, humid environment the bacteria transformed the hydrogel surface into one made of cellulose. Cellulose is only made on the surface of the hydrogel because that is where most of the oxygen is—therefore, the method produces thin coatings suitable for wound treatment.

During the development of the bacteria-containing hydrogel, the gel’s flow properties posed a particular challenge: the ink must be fluid enough to be forced through the pressure nozzle. The consistency of the ink also affects the bacteria’s mobility. The stiffer the ink, the harder it is for them to move. If the hydrogel is too stiff, however, Acetobacter secretes less cellulose. At the same time, the printed objects must be sturdy enough to support the weight of subsequent layers. If they are too fluid, it is not possible to print stable structures, as these collapse under the weight exerted on them. “The ink must be as viscous as toothpaste and have the consistency of Nivea hand cream,” is how Manuel Schaffner, one of the first authors of the research paper describes the successful formula.

However, the research is still in its initial stages. “Printing using bacteria-containing hydrogels has enormous potential, as there is such a wide range of useful bacteria out there,” says one of the first authors, Patrick Rühs. He blames the bad reputation attached to microorganisms for the almost total lack of existing research into additive methods using bacteria. “Most people only associate bacteria with diseases, but we actually couldn’t survive without bacteria,” he says. However, the researchers believe their new ink is completely safe. The bacteria they use are all harmless and beneficial.