The future of Biofuel: Petite Poplars one of the pacific Northwest best bets

Wood from a common tree may one day factor prominently in meeting transportation fuel needs, according to scientists at the University of Washington.

In the quest to produce affordable biofuels, poplars are one of the Pacific Northwest’s best bets—the trees are abundant, fast-growing, adaptable to many terrains, and their wood can become substances used in biofuel and high-value chemicals that we rely on in our daily lives.

University of Washington researchers are testing the production of younger poplar trees that could be harvested more frequently—after only two or three years instead of the usual 10- to 20-year cycle—to make the trees practical for the biofuels market. The team is trying to convert the entire tree into ethanol and bio oil, a biologically derived oil product, using two separate processes.

“Our research proved that poplar coppice can be a good option to meet the cheap, high-volume criteria of biofuel feedstock,” said lead author Chang Dou on both papers, a doctoral student in the UW’s Bioresource Science and Engineering program. “Our findings are significant for the future biofuel industry, and the ultimate goal is to make poplar coppice biofuel a step closer to the pump.”

The UW researchers believe that poplar coppice has the potential to create alternative fuels that ‘make economic sense’ and could therefore be competitive in the petroleum dominated fuel market.

Biofuels emit fewer pollutants than fossil fuels such as gasoline. In addition, poplar and related plants are vital managers of atmospheric carbon. Trees store captured carbon dioxide in their leaves, branches, stems, and roots. This natural process provides opportunities to improve carbon removal from the air by producing trees that effectively shuttle and store more carbon below ground in their roots and the soil. Moreover, bioenergy crops re-absorb carbon dioxide emitted when biofuels are consumed, creating a cycle that is essentially carbon neutral.

Poplar’s extraordinarily rapid growth, and its relatively compact genome size of 480 million nucleotide units, 40 times smaller than the genome of pine, are among the many features that led researchers to target poplar as a model crop for biofuels production.

Under optimal conditions, poplars can add a dozen feet of growth each year and reach maturity in as few as four years, permitting selective breeding for large-scale sustainable plantation forestry. This rapid growth coupled with conversion of the lignocellulosic portion of the plant to ethanol has the potential to provide a renewable energy resource along with a reduction of greenhouse gases.

“We have the environmental incentives to produce fuels and chemicals from renewable resources, but right now, they aren’t enough to compete with low oil prices. That’s the problem,” said Renata Bura, a UW associate professor in the School of Environmental and Forest Sciences and the senior author.

The UW team first tested whether entire young poplar trees could be converted into sugar by a process that uses high temperature, pressure and enzymes to break down the wood materials into sugar. From there, it is possible to make ethanol, acetic acid, lactic acid and other valuable chemicals by fermenting the sugar.

After processing the trees, the researchers found that leaves are poor performers and lowered the overall sugar output, not just because leaves are naturally low in sugar, but they also contain other chemicals that impede the sugar-releasing process. When scaled up to a commercial operation, leaves should be removed and may be used for other purposes, such as feed for animals.

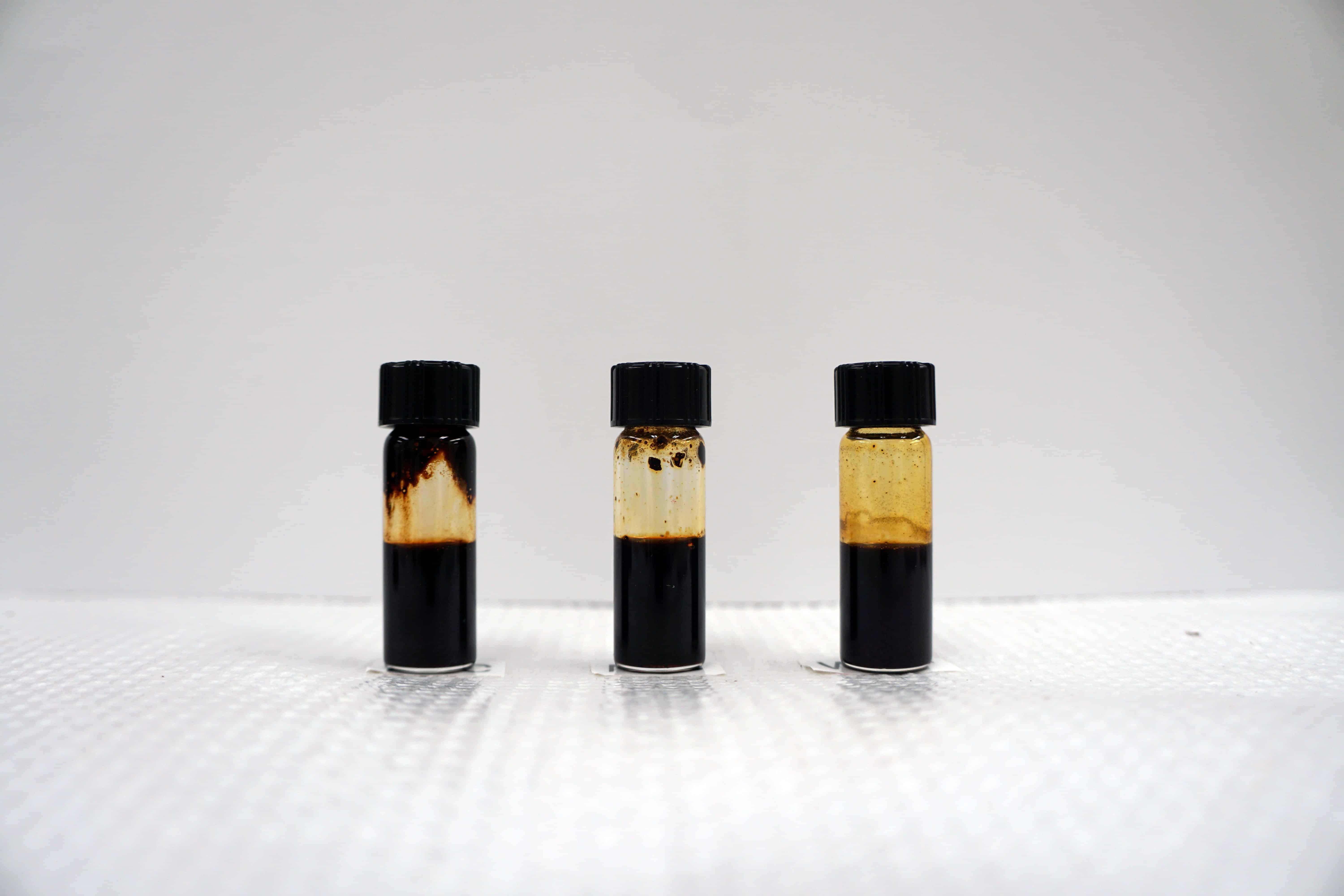

They also tested whole poplar trees from the same plot in another conversion process that uses much higher heat — upwards of 500 degrees Celsius — to transform the tree materials directly to bio oil in a process called “pyrolysis.” Research is underway to convert this dark brown oil to a transportation fuel that resembles gasoline or diesel.

Future poplar production plants could leverage both methods, weighing factors like the current cost of materials or the dollar value of the products being made to determine which method makes more financial sense, Dou explained.

Ultimately, the researchers believe that coppice poplar is likely to be the best balance of cost and reliability for Pacific Northwest growers to produce biofuels.

“Currently, we are looking at how we can grow poplar for monetised ecosystem services,” Bura said. “In the future, we envision a bio-based industry that will provide multiple environmental benefits, will invigorate rural communities and will serve as a bridge to a fully developed biofuels industry.”