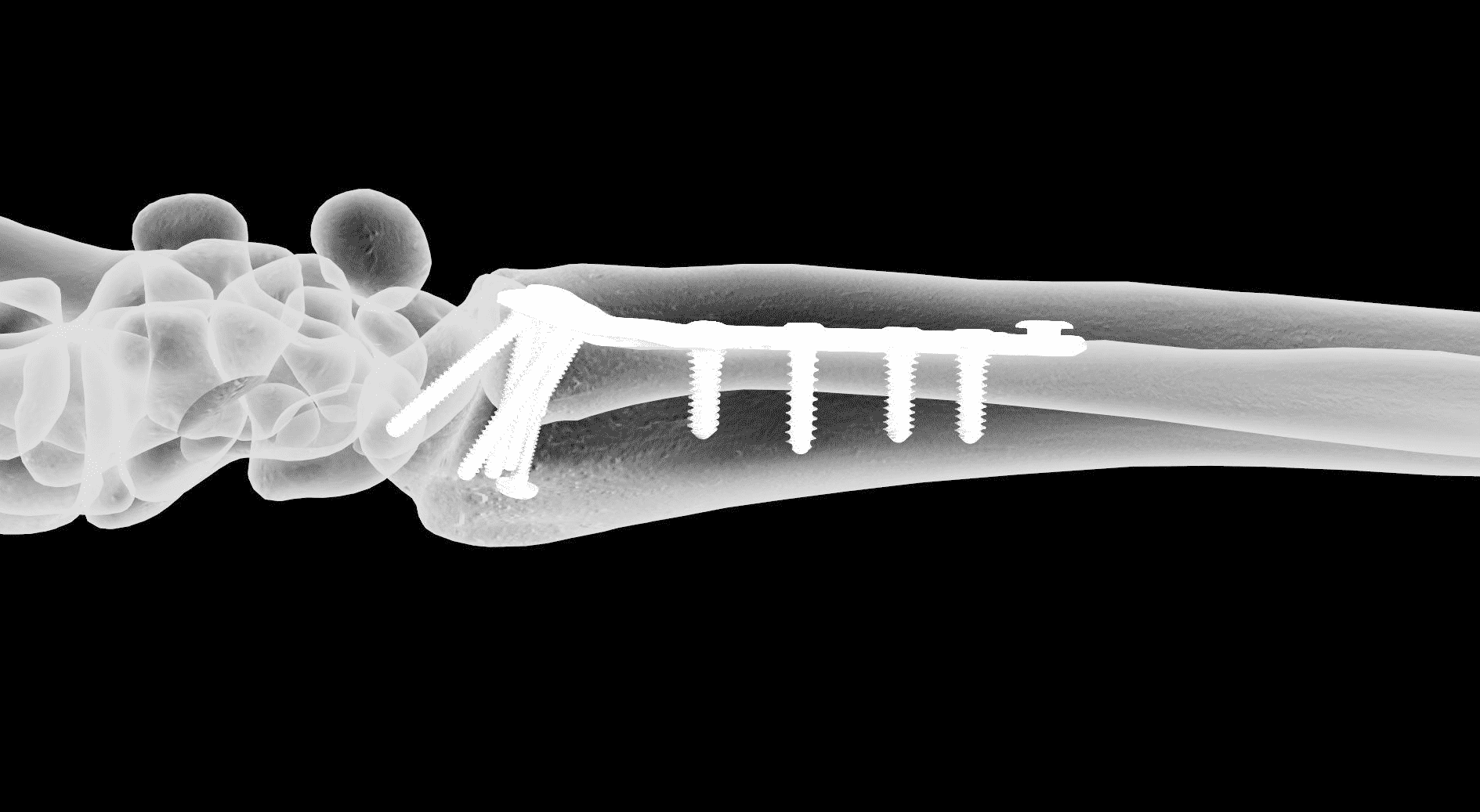

Mending Broken Bone Using Human Bone As Surgical Screws

A broken bone must be carefully stabilized and supported until it is strong enough to handle the body’s weight and movement. The screws used by doctors to repair broken bones and torn ligaments enable recovery from a wide range of injuries. Unfortunately, they also leave holes in bones, require secondary surgery for removal, and make going through airport security a real pain. Also, another major concern included is immunogenicity. Eventually, these have to be removed with an additional surgical procedure.

Therefore, bioengineers at the TU Graz, Austria, have now devised an alternative approach to this problem by developing surgical screws from donated human bone for foot and jaw surgery.

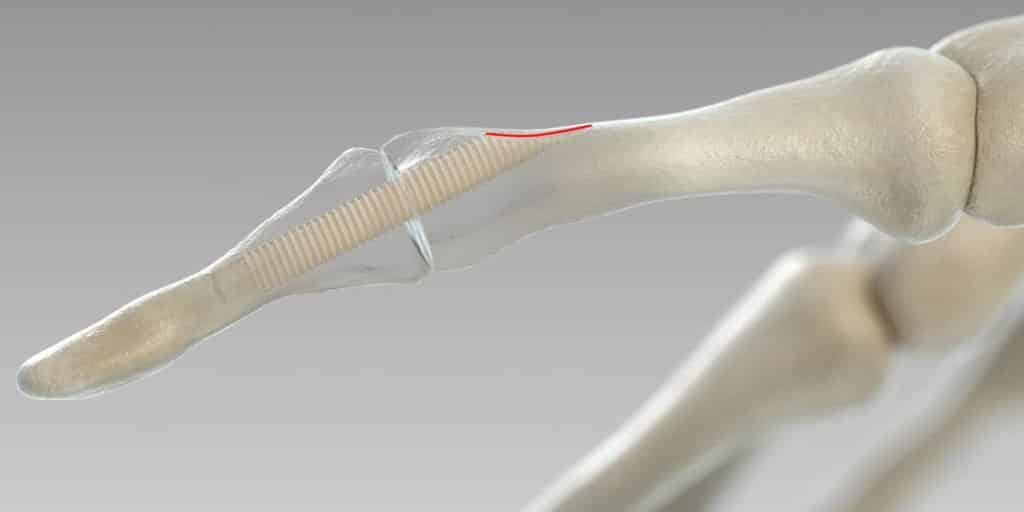

The group’s exciting technology, the Shark Screw, is made from the compact middle layers of the thigh bone. The screw connects fragments of bone and acts as a scaffold into which new cells can incorpora

te themselves. This means the screw is accepted by the body and becomes part of the healed bone.

The donated bone is collected from organ donors and must be carefully selected as suitable to be adapted into a surgical implant. A particularly important consideration is the size of the miniature tubes which contain blood vessels and nerves, the Harversian canals, which strongly affect the performance of the screws.

So what exactly are the advantages of screws made of donated bone material? The metal doesn’t have to be removed and a second operation – as unpleasant as it is risky and expensive – doesn’t have to be carried out because the donated material has completely healed into the bones. So well healed that the transplant is no longer visible in an x-ray after one year. On top of this, the body recognises the bone screws as belonging to its own body, and danger of infection and complications is reduced to a minimum. The Shark Screw is being produced from the start-up surgebright, which was founded in 2016, in cooperation with the German Institute for Tissue and Cell Replacement (DIZG) in Berlin. The patented technology is already being used in 14 Austrian hospitals.

“There is a big difference between working with metal screws and screws made of biomaterial,” said Dr Gerhard Sommer of the Institute of Biomechanics at TU Graz, who is working on the project. “The mechanical principles are the same, but we also have to consider that donated bone material shrinks somewhat during sterilisation and two hours after the operation expands again in the body and becomes more elastic.”

“We have to completely rethink the bone screw for application in foot and jaw surgery and want to develop prototypes for application in foot and jaw surgery,” said Dr Sommer.

“In maxillary surgery, extremely small screws are necessary, approximately 20mm long, which have to withstand great stresses because relative to size, the jaw muscle is the most powerful muscle in the human body. In foot surgery, although the screws are bigger, between four and six centimetres long, they are also exposed to large forces.”

The team is currently investigating the forces within the bone structure of the foot and jaw, in order to determine the necessary strength of the new bone screws: tweaking the design of the thread could improve the strength considerably.

this is good atical..