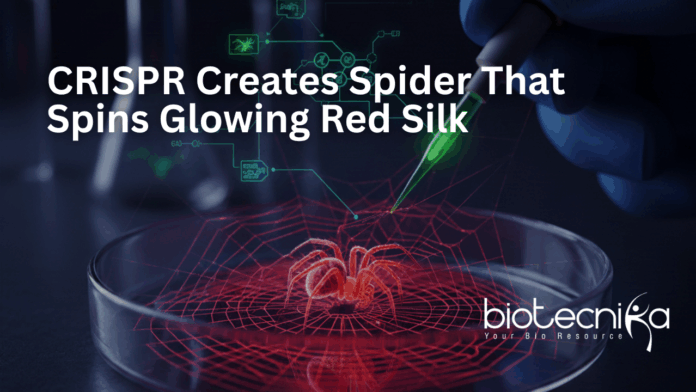

CRISPR Lets Scientists Create the World’s First Spider That Spins Glowing Red Silk

What if one of nature’s toughest fibers could be redesigned—directly from the creature that spins it? For years, researchers dreamed of editing spiders the same way they edit flies, fish, or crops. But spiders, with their sensitive biology and solitary personalities, refused to cooperate. That barrier finally fell in a German lab, where scientists used CRISPR to guide a house spider into weaving fluorescent red silk—a historic first in genome editing and a breakthrough for materials science, opening new possibilities for designing high-performance, bioengineered fibers.

Spiders might build extraordinary materials, but they are challenging research partners. Their genomes are packed with repeats, their diversity is enormous, and most species dislike living near others. Put two in a single container, and one may not walk out. Even small changes in humidity or vibration can stress them.

This made spiders outliers in genetics. While mosquitoes and fruit flies became research staples, spiders remained largely untouched—an ironic gap, considering how much interest their silk attracts in materials science.

What CRISPR Changed This Time:

A team at the University of Bayreuth turned to Parasteatoda tepidariorum, a hardy house spider already used in developmental studies. Using CRISPR, they inserted a short DNA sequence encoding a fluorescent tag directly into a silk-protein gene.

Instead of turning a gene off or cutting a region, they performed a delicate genome insertion—adding a glowing marker that the spider would naturally include in its silk proteins.

For the first time, a spider didn’t just receive an edit—it passed it on to its offspring, proving the change was stable and heritable.

The Art of Editing a Spider Embryo:

The experiment required patience and precision. Early embryos were injected when their cells were still dividing rapidly, giving the edit a chance to spread throughout the body. Handling had to be brief; the embryos are extremely sensitive to pressure and temperature shifts.

Only after the females recovered were they allowed to mate, and their offspring were carefully tracked to confirm the fluorescent tag had taken hold.

The approach balanced welfare and technical accuracy—a rare combination in arachnid research.

What the Researchers Built: Red Silk That Still Performs Like Silk:

Under the microscope, the modified threads glowed a vivid cherry red. Under regular light, they looked perfectly normal. Importantly, the glowing silk kept its famous performance traits:

- strong yet lightweight,

- flexible, and elastic,

- high toughness comparable to natural dragline silk

That last point matters. Engineering often introduces trade-offs: add function, lose performance. Here, the researchers gained a visual signal without weakening the fiber, a valuable win for bioengineered materials.

Why This Matters for Materials Science:

Spider silk blends strength, stretch, and low weight in a way that synthetic fibers struggle to match. With programmable features added through genome editing, the possibilities widen dramatically:

- sutures that fluoresce when strained

- wearable fabrics with built-in sensors

- micro-cables for soft robotics

- biofilters that capture toxins or microplastics

- research tools that reveal how silk forms inside the animal

The fluorescent tag itself is also a powerful scientific tool. It lets researchers track silk assembly in real time—from gland to spinneret to final thread—something never possible before.

A Second Test: Switching a Gene Off:

To confirm that their editing pipeline worked, the group also performed a classic CRISPR knockout. They disabled a gene known as so, suspected to help form spider eyes. Edited hatchlings emerged without eyes, offering clear confirmation of the gene’s role and reinforcing the reliability of their method.

Important Limitations Still Remain:

Scaling production is a longstanding challenge. Spiders cannot be farmed like silkworms; they need space, stable environments, and isolation. Future work may blend approaches—use edited spiders to discover new silk functions, then reproduce those features in silkworms or industrial bioreactors at scale.

There are also regulatory and ecological considerations. Labs must enforce careful containment, and environmental impact studies will be essential before these materials move beyond research facilities.

A Step Toward Programmable Nature-Built Fibers:

This breakthrough doesn’t solve the puzzle of large-scale spider silk production, but it shifts what’s possible. By editing the spider itself—rather than producing silk proteins in goats, bacteria, or silkworms—scientists tap directly into nature’s own spinning machinery.

If future studies preserve both mechanics and added functionality, we may soon see a new class of programmable, biologically spun fibers that merge performance with purpose—an exciting frontier where genetics and materials science meet.